What is pressure vessel?

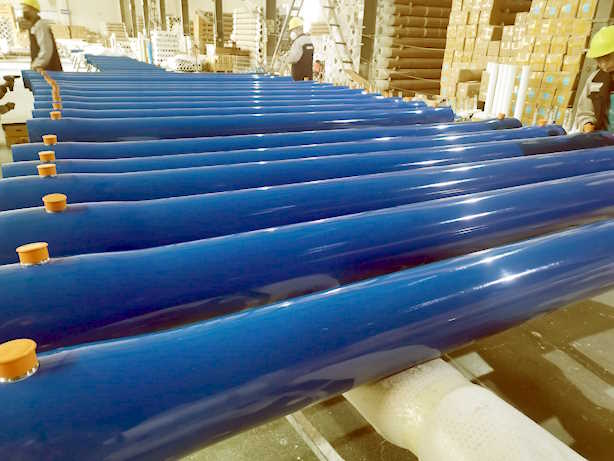

In industrial water purification systems, reverse osmosis membrane elements are placed inside pressurized chambers, which are called Perschroussel. Perschrusel’s task is to place the membranes in series and make it possible for water to pass through the RO membranes ( membranes for industrial water treatment ) under the desired pressure. Membrane vessels can be used in different sizes depending on the capacity and design of the reverse osmosis system. Membranes inside Perchrusel are usually connected by plastic pipes with o-rings on them, which are called interconnectors. Each pressure vessel is enclosed on its sides by closely spaced chambers called “end caps”. The end caps are designed to withstand the operating pressure of the system.

All kinds of industrial plants

For a better answer to the question of what is Perschrusel, it is necessary to examine the types of industrial water purification Perschrusel. In general, pressure vessels can be divided based on the capacity of the number of membranes, diameter, inlet position, and operating pressure. We will explain each one below.

Based on the number of elements (members)

Vessels are made in the number of 1 to 8 elements, which number is determined in the design phase of the RO system. Normally, 6-element filters are used in industrial water purification systems. A 6-cell membrane means that each cell can accommodate 6 membranes. Of course, in some sea water desalination plants, 7-element preheaters are also used.

Based on the diameter of the membranes

Based on the diameter of the membrane to be used, the industrial Percherusel is produced in two sizes, 4 inches and 8 inches, each of which is used for a specific capacity:

- 4 inch Percherusel: in the design and production of a semi-industrial water purification device with a maximum capacity of up to 50 cubic meters per day

- 8-inch Percherusel: in the design and production of industrial water purification devices with capacities higher than 50 cubic meters per day

Based on input type

If we want to divide the industrial membrane vessel according to the inlet and outlet position of the feed water into the vessel, we have to mention two important categories of inlet from the side (side port) and inlet from the end (end port). In the side port mode, the water inlet and outlet path is placed on the body of the perchrusel, while in the end type, the water inlet and outlet are embedded on the end caps of the perchrusel.

Read more: Time to replace the water purification membrane filter

Multiport pressure vessel

Another type of router is the multiple port model, which is used for high-capacity systems, and each router is connected to its neighboring routers.

based on operating pressure

The working pressure in the industrial water treatment device determines what type of pressure tolerance should be used. In the following, let’s briefly state what type of filter is used in which field of water purification:

- 300 PSI Pressure Washer: Saltwater and Well Water Purifiers (BWRO)

- 450-600 PSI Perchrosel: Saltwater machines with 10,000 ppm TDS

- Pressure washers with pressure of 1000-1200 PSI: marine desalination units (SWRO)

High-pressure industrial components

Certainly, our knowledge about what vascular membranes are becomes possible and more complete by knowing its components. In the following, we briefly mention its main components.

- Shell or Membrane Housing: It is the Percherusel body that is usually made of fiberglass and the membranes are placed inside it.

- Victaulic Clamp: A two-part and grooved structure that is used in high pressure pipes and is used to connect the inlet and outlet pipes of the feed to the Percherusel.

- End cap: It is a cap that is placed at the upstream and downstream ends of the vessel and seals the vessel chamber.

- Permeate Connectors: pipe connections that connect to the primary and end membranes inside the Perchrocell and connect to the end cap to establish the path of permeate water outside the Perchrocell.

High performance of industrial water purifier

In industrial water purification systems, it is necessary for water to flow under a certain pressure on the reverse osmosis elements or membranes so that the purification operation is performed well. Another necessity of reverse osmosis systems that allows recovery of water is the number of elements or membranes that are placed in series and one after the other in the RO system. For example, in a Barkish RO system, you need 6 series elements to recover up to 50%. Here, in the first place, the Percherusel houses this number of membranes in series so that we can perform the desired recovery, and in the second place, they provide the possibility of applying the desired pressure that is necessary for the purification operation. This pressure is hydraulic, which is created by a high pressure pump.